Operator Training Simulator

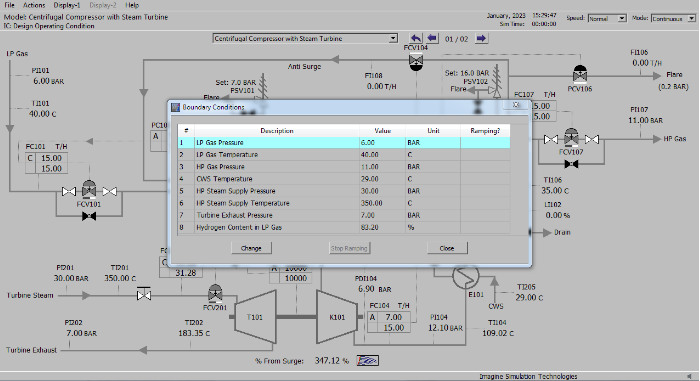

Imagine Simulation Technologies develops simulators with generic process models for common processes for training plant personnel on process fundamentals. We also undertake development of custom simulators as per client specifications with model & conditions matching the customer’s plant, including Operator Training Simulators (OTS).

Simulator

-

Dynamic real-time simulation – Digital Twin

-

Can be used for steady state studies

-

Generic modules for basic learning and entry level training

-

Custom simulation development to client specific plant

-

Ideal for practicing all plant operations including startup, shutdown, emergency and failure responding, what-if studies, operational benefit analysis, controller tuning and so on.

-

All features of a typical operator training simulator included with many views intended to go beyond training.

-

Easy to operate with intuitive UI. Can add DCS emulation

Customer Advantage

-

Effective training with real time operation

-

Graded approach; generic modules for understanding basic unit operation and migrating to larger process specific to your plant

-

Check the results of operations in advance; eliminate mistakes in operation

-

‘What-if’ studies using the current plant conditions leading to optimal operating conditions

-

Verify controller tuning, find optimal tuning constants for each loop

-

Startup/shutdown planning

-

Bottleneck analysis and efficiency improvement

-

Practice unlimited number of operations including major emergency situations

Cost Benefit

-

Operational Savings & Minimizing Production Loss: Plant operators become trained for all situations, eliminating unanticipated equipment failure, frequent off-spec production, unit trip, etc.

-

Increased Safety: Adequate training using the right tools can ensure safe operation, which is of utmost importance.

-

Lower Training Costs: With our intuitive interface, the training can be instructor-less.

-

Higher Flexibility: Flexible training schedule due to 24/7 availability of the simulator.

-

Lower Production Costs: Applying optimal operating conditions that have been validated on the simulator eliminates the traditional trial & error approach in arriving at the optimal operations.

-

Faster Startups & Shutdowns & Lesser Off-Spec Production